Printing and packing are critical in Pace Biotech, which allows us to always ensure our injections and medicines reach end consumers safely while adhering to tight regulatory criteria. Here’s an overview of how printing & packing functions are managed in our pharmaceutical manufacturing company:

Printing and packing are critical in Pace Biotech, which allows us to always ensure our injections and medicines reach end consumers safely while adhering to tight regulatory criteria. Here’s an overview of how printing & packing functions are managed in our pharmaceutical manufacturing company:

Importance of printing and packaging

We always ensure that each of our injectable products is appropriately labelled with important information such as drug name, dose, batch number, and expiration date. Here in printing and packing processes, we surely follow local and international regulations (for example, FDA, EMA, and WHO-GMP requirements). Thus, it allows us to have high-quality printing and packaging to improve our product appeal and increase consumer confidence. Most importantly, our packaging protects sensitive biotechnology products from environmental hazards such as light, moisture, and temperature changes.

Key features of our printing and packaging in biotechnology

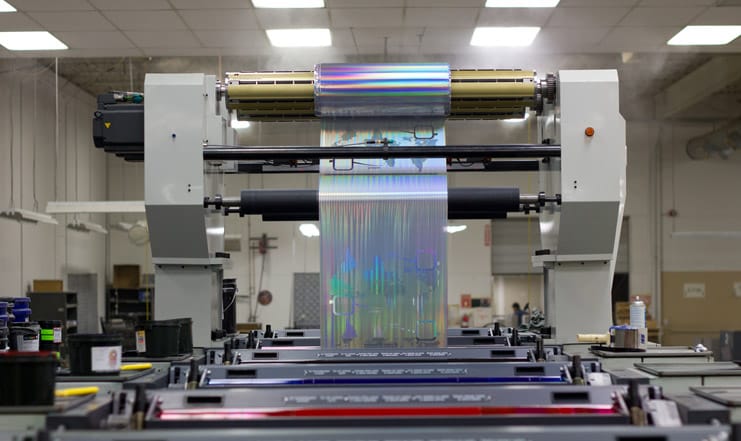

We know that high-precision printing is required for small but important elements like barcodes, QR codes, and microscopic anti-counterfeit measures. Also, we include legally required facts, such as the product name, composition, manufacturer information, storage instructions, and lot/batch numbers. In this, we also use batch-specific information and ensure traceability and avoid product forgery using holograms, security inks, or invisible codes. Moreover, in packing, the primary packaging involves direct interaction with the product, such as vials for injectables, pre-filled syringes for biologics, and blister packs of oral pharmaceuticals. Then in secondary packaging, we include boxes, cartons, and pouches used to group primary products.

Specialised packaging for biotechnology products

Because of the sensitive nature of our biotechnology medications, we always provide one-of-a-kind packaging options. We maintain specified temperatures (e.g., 2°C-8°C or -20°C) during transport and storage. Moreover, we have sterile packaging that provides aseptic conditions for injectables and biologics, and also our moisture-resistant packaging protects hygroscopic compositions from deterioration.

Automation and technology for printing and packaging

We have advanced systems for ensuring traceability using unique barcodes or serialised numbers. Moreover, we increase efficiency and precision while reducing human error. For this, we also use digital printing that enables instant customisation and reduces lead times.